Our Fiber Eco-Review

We have created our own Fiber Eco-Review, using resources such as the MADE-BY Fibres Environmental Benchmark, Textile Exchange Preferred Fiber Market Report and other studies on the environmental impact of each of the fibers. Here, we have only taken the fiber production into consideration, and not the dyeing and finishing.

We have divided fibers in 2 categories according to their environmental impact:

The Fibers We Like

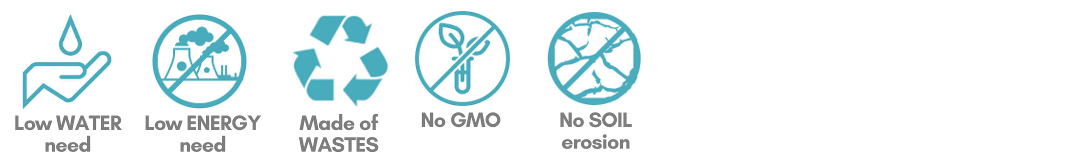

The FIBERS WE LIKE are “eco-friendly” fibers, which means that their production process has a low impact on the environment and meets at least half of the below criteria:

RECYCLED FIBERS

made with waste material

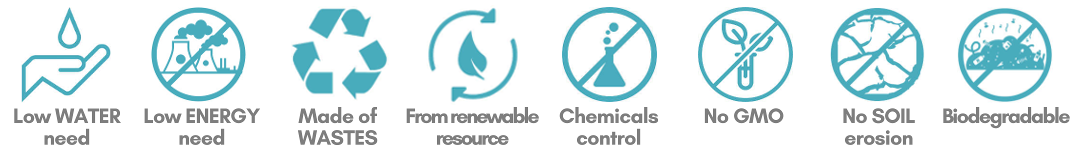

ANIMAL-BASED FIBERS

produced in sustainable way

The Fibers We Avoid

The FIBERS WE AVOID have one or several of the below notably negative environmental impact. We consider these impacts serious enough to try to discard these fibers from our wardrobe: